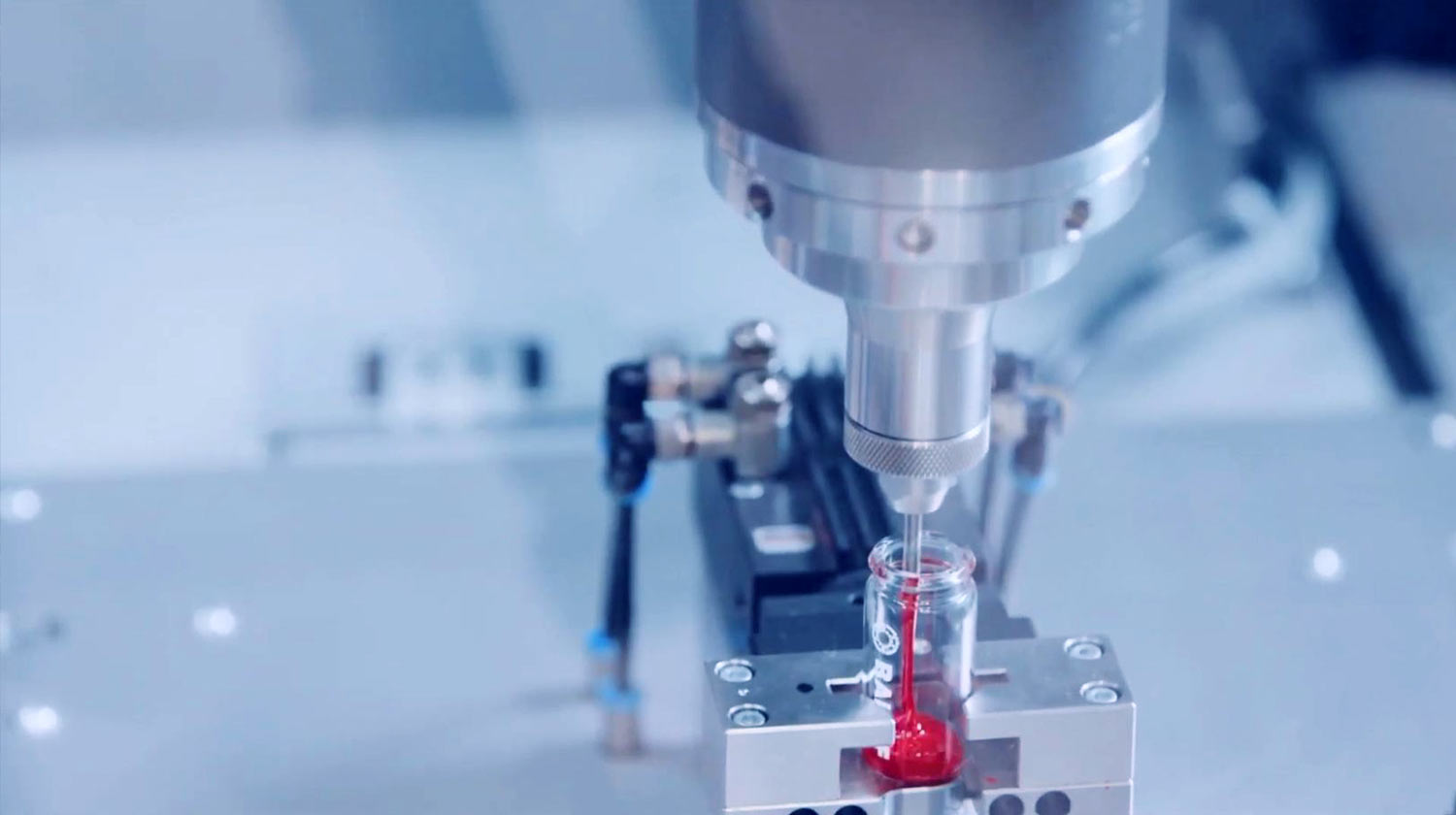

An executable digital twin makes the "unmeasurable" visible

... and enables live control, for which no data was previously available

Intelligent machine control requires data—but in reality, many crucial process variables simply cannot be measured. This is exactly where RAMPF's Executable Digital Twin comes in: a model runs parallel to the real system, calculates the otherwise invisible variables in real time, and makes them available to the control system. This provides reliable data for decisions that were previously based only on gut feeling or approximations – and the machine can independently adjust and optimize its behavior.

The whole story about the executable digital twin:

Technology, practice, learnings

RAMPF, Novicos, and Siemens in open discussion

In an SPS panel discussion, RAMPF, Novicos, and Siemens openly discuss how the Executable Digital Twin came about in practice: which process variables could not really be measured, how the model closes these gaps, what compromises were necessary, and where there were setbacks. If you want to understand not only the "what," but also the "how exactly" and "at what cost," you will find the complete perspective of all participants here.

Do you need data that you cannot measure?

Do you have a specific challenge and would like to find out whether there are ways to obtain reliable data in this area too? I would be happy to advise you on your options.